What type of hydraulic pump does the excavator use?

Excavators are heavy construction equipment designed for digging and moving large amounts of soil, rocks, and other materials. These versatile machines consist of several components, and one essential part is the hydraulic pump. Hydraulic pumps play a crucial role in powering various hydraulic systems within an excavator, including the bucket, arm, and boom movements. In this product description, we will explore the different types of hydraulic pumps commonly used in excavators, their functions, and their benefits.

1. Gear pumps:

Gear pumps are one of the most common types of hydraulic pumps used in excavators. They consist of two intermeshing gears (usually spur gears) within a housing. As the gears rotate, the fluid is drawn into the suction side and forced out through the discharge side, creating pressure. Gear pumps are reliable and relatively inexpensive, making them an ideal choice for many excavator applications. They are capable of providing high flow rates but may not generate very high pressure levels.

2. Vane pumps:

Vane pumps are another popular choice in excavators due to their compact size, efficiency, and ability to handle a wide range of operating speeds. These pumps consist of a rotor with vanes that slide in and out of machined slots inside the pump housing, creating a vacuum and pressure. Vane pumps offer good levels of efficiency, are well-suited for high-pressure applications, and have low noise levels during operation. They are commonly used in both medium-sized and large excavators.

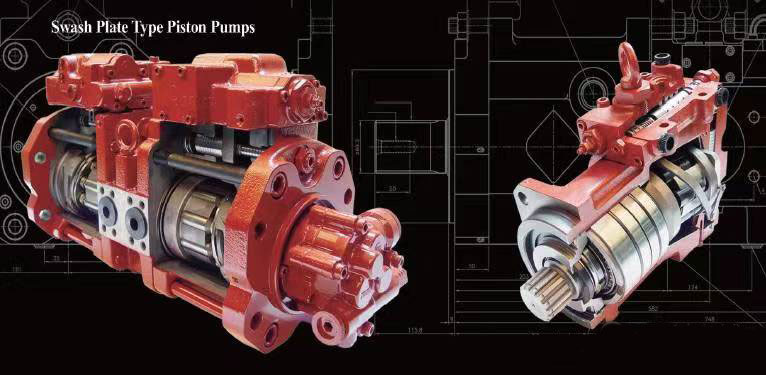

3. Piston pumps:

Piston pumps are known for their high power density and ability to handle heavy-duty excavator tasks. These pumps utilize a set of reciprocating pistons to pressurize the hydraulic fluid. There are two main types of piston pumps used in excavators: axial piston pumps and radial piston pumps.

– Axial piston pumps have pistons arranged in a circular pattern around a central drive shaft. The pistons move in and out of the cylinder block as the shaft rotates, generating the necessary hydraulic pressure. These pumps provide high efficiency, excellent control, and precise movements, making them suitable for high-performance excavators.

– Radial piston pumps work by pushing pistons outwards from the center to generate pressure. The pistons move in radial grooves inside the housing, creating a pumping action. Radial piston pumps are known for their ability to generate high pressures reliably, which makes them suitable for heavy-duty excavator applications.

Both axial and radial piston pumps are ideal for excavators that require high power output and high-pressure capabilities, such as large-sized earth-moving tasks.

4. Variable Displacement Pumps:

Variable displacement pumps are designed to provide adjustable flow rates based on the demand of the hydraulic system. These pumps can vary the displacement (amount of fluid pumped per revolution) based on the load requirements, enabling optimized energy consumption and improved efficiency. Variable displacement pumps are commonly used in modern excavators to enhance their overall performance and fuel efficiency.

In conclusion, excavators rely on hydraulic pumps to enable the various hydraulic functions needed to perform their tasks efficiently. Gear pumps, vane pumps, piston pumps (both axial and radial), and variable displacement pumps all have their advantages and are chosen based on the specific requirements of the excavator. Whether it’s providing high flow rates, handling heavy loads, generating high pressure, or optimizing energy consumption, the right choice of hydraulic pump ensures reliable and efficient operation for excavators in different applications and industries.